Engineering technology is a complex field focused on the practical applications of engineering to design, 开发, 改进技术. Professionals who work in this field combine a knowledge of engineering with a hands-on grasp of manufacturing to produce products, 流程, 和系统规范. 让我们看看其中的一些方法 engineering technology has changed 现代制造业 植物.

制造业的演变

Engineering technology is a major part of 现代制造业, enabling factories to produce products efficiently. 但事情并不总是这样.

制造业简史

The Industrial Revolution of the 18th century brought huge advances in machinery, 运输, 和沟通, all of which helped make manufacturing a reality. Never before had mass production been possible—spurring the pace of economic growth from a trot to a gallop.

工程技术概论

到了20世纪, assembly lines were the newest factory revelation, 尤其是在汽车行业. The ability to mass produce and quickly assemble advanced products like cars once again changed the game. 从那时起, manufacturing technology has advanced even more rapidly, 彻底改变磁场. Automation and robotics have since taken over many 流程 of 开发ment, 把人的注意力转移到别处.

Impact of 工程技术 on Manufacturing Today

这些天, the humans you’ll find working in factory settings are more likely to be programming and repairing the manufacturing equipment or designing new applications for the technology. New industries are created every day with breakthroughs in semiconductors, 生物技术, 和人工智能(AI).

And it’s all thanks to engineering technology. This industry is responsible for automating manufacturing 流程 and continues to drive innovation and economic progress into the future.

工程技术 in Modern Manufacturing

Engineering technologists work to improve efficiency, increase productivity, and reduce costs. 几个关键 engineering technology players in 现代制造业 facilities 包括:

- 自动化: Computer-controlled systems which take on planning, 调度, 质量控制, 提高精度和一致性.

- 机器人: Programmable machines which handle repetitive tasks faster and with greater accuracy than humans. They are also able to work in dangerous or hard-to-reach environments.

- 3 d打印: Machines which can produce complex parts, layer by layer, from digital designs. This reduces not only costs but also inventory wait times.

- 增强现实: Overlays digital information or media atop the real-world environment, potentially providing real-time guidance and training to workers.

- 人工智能: AI and 机器学习 algorithms can analyze data and make predictions or suggestions, helpful for increasing efficiency and reducing costs in many ways.

The role of engineering technology in manufacturing is quite significant. Its contributions improve quality control and allow for product innovation.

工程技术 for Quality Control

When manufacturing 植物 can easily monitor and test products with precision and consistency, 质量控制自然提高. Engineering technology is to thank for the automation and robotics which enable this consistency in production and quality.

Examples include non-destructive testing (NDT), x射线成像, 各种类型的传感器, 数据分析, all of which help factories prevent small issues from becoming big (and expensive) problems.

工程技术 for Product Innovation

New technology always has new and unprecedented applications, leading to further inspiration and innovation. Examples include 3D printing, which has limitless applications. 3D printing is useful in manufacturing facilities for fabricating custom 组件 or parts, which may have previously been expensive, 需要很长的运输时间, 或者根本不存在于市场上.

更多的例子包括人工智能, 机器学习, and data analyzation used to identify market trends—which could highlight a need, 这可能导致产品创新.

工程技术 for Optimization and Communication

Optimizing production is always the goal of manufacturing facilities. When computer-aided design (CAD) software and simulations are used in the design process, 生产更加顺畅. Other examples include automation using programmable logic controllers (PLCs).

Benefits of 工程技术 in Manufacturing

Engineering technology helps manufacturing 植物 reduce costs and increase efficiency. This is achievable through a few factors:

- Streamlined production 流程 through automation

- Product consistency 质量控制 through robotics

- Reduced costs because of increased efficiency, improved quality and consistency

- Increased workplace safety as robotics and automation take over dangerous tasks

Modern manufacturing would look quite different without the advances of engineering technology.

Challenges of Implementing 工程技术 in Manufacturing

Despite the many benefits of engineering technology for the manufacturing industry, 挑战也存在:

- 投资: Automation and robotics technology are expensive to purchase, 安装, and 维护. It requires a significant investment in hardware as well as software.

- 集成: Existing infrastructure may be quite old and require modifications to accommodate new technology.

- 培训: The plant workers must shift from manufacturing products to repairing manufacturing equipment. They will need to be educated in how to work with the new technology.

- 网络安全: New technology is largely interconnected, meaning that all systems must be carefully safeguarded from hackers and other digital threats.

- 进步: As quickly as technology has progressed just in recent memory, expect it to continue to advance! Even the most cutting-edge tech will be obsolete someday.

The challenges of updating a manufacturing facility can be overcome by taking proactive steps before undertaking an entire factory renovation:

- 详细的实施计划: An assessment of the facilities’ existing infrastructure must be performed to determine what technology would be most beneficial, 应该放在哪里, and how it can be effectively integrated.

- 让员工参与实施: Soliciting employee feedback or otherwise involving them in the process can reduce staff resistance, as can thorough training in the new systems 和流程.

- 与持份者合作: Expert partners may be able to offer guidance on best practices, 提供支持, and give advice from prior experiences in the industry.

- 正在进行评估: Reviewing performance data on a regular basis can help ensure a smoother transition. Document this process to streamline the experience for the next major factory upgrade!

A strategic approach is the best way to handle such a large undertaking with minimal risk.

Future of 工程技术 in Manufacturing

The advanced engineering technology used in manufacturing facilities today will continue to adapt and progress, leading to greater precision and consistency in production.

The use of data analytics and AI will only gather more and more data, which can help optimize 流程 and identify areas for improvement. 3D printing and the Internet of Things (IoT) are also expected to play larger roles in manufacturing 植物, 随着新功能的发现.

这些技术, as well as the new innovations they will inspire, have the power to change manufacturing as we know it. Are you interested in being a part of this shift?

How to Become an Engineering Technologist

You could be a force for change in factories around the world with a Bachelor of Science in 工程技术, in any of these dynamic concentrations:

- 机械工程技术: 你可以学习做实验, 然后分析和解释结果, to design and improve mechanical 流程.

- 电子工程技术: You could learn to design and build electronic systems using analog and digital electronics, to implement and 维护 computer systems.

- Electronic Systems 工程技术 (ESET): You could be the link uniting engineers and technicians, 在团队中进行设计, 安装, 维护, 修复系统, 组件, 和流程.

- 机电一体化: You could learn to 开发 and troubleshoot robotics, 可编程序控制器, 集成系统.

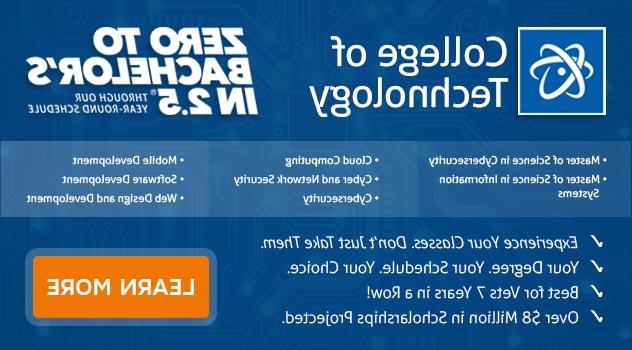

At 为大学的y you could earn your bachelor’s degree in as little as 2.5年, thanks to our accelerated degree programs. You could even graduate with valuable experience on your resume, due to our hands-on approach to learning, 先进技术实验室, and our emphasis on industry externships. Contact our friendly admissions advisors to discuss earning your Bachelor of Science in 工程技术 in as little as 2.5年.

它可能是 你做过的最好的决定!

DISCLAIMER - 十大正规网堵平台 makes no claim, 保修, or guarantee as to actual employability or earning potential to current, past or future students or graduates of any educational program we offer. The 十大正规网堵平台 website is published for informational purposes only. Every effort is made to ensure the accuracy of information contained on the 十大正规平台.edu domain; however, no 保修 of accuracy is made. No contractual rights, either expressed or implied, are created by its content.